1

/

из

5

Oriwhiz Replace Parts

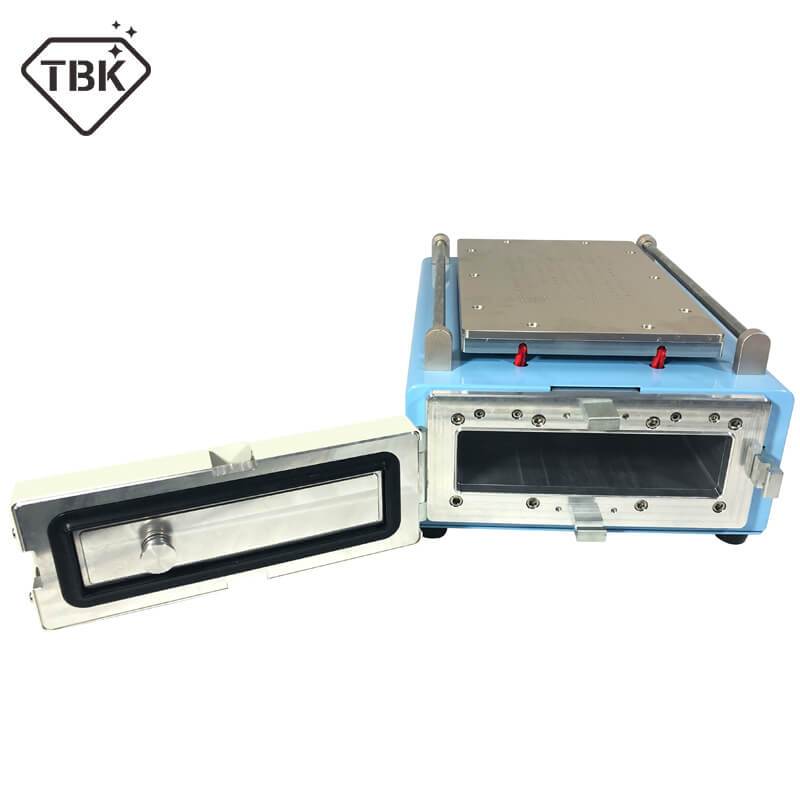

NEW TBK 968C 10 inch plate heating separate machine built-in mini debubbler with wire separating lcd touch screen damaged repair

NEW TBK 968C 10 inch plate heating separate machine built-in mini debubbler with wire separating lcd touch screen damaged repair

Обычная цена

$476.00 USD

Обычная цена

Цена со скидкой

$476.00 USD

Цена за единицу

/

за

Стоимость доставки рассчитывается при оформлении заказа.

Не удалось загрузить сведения о доступности самовывоза

Product Features:

1.Desigh of safety lock and integrated debubble area bubble remove separating

2.curved screen, straight screen and flat PAD are all supported

3.Solid without weiding spots

Specifications:

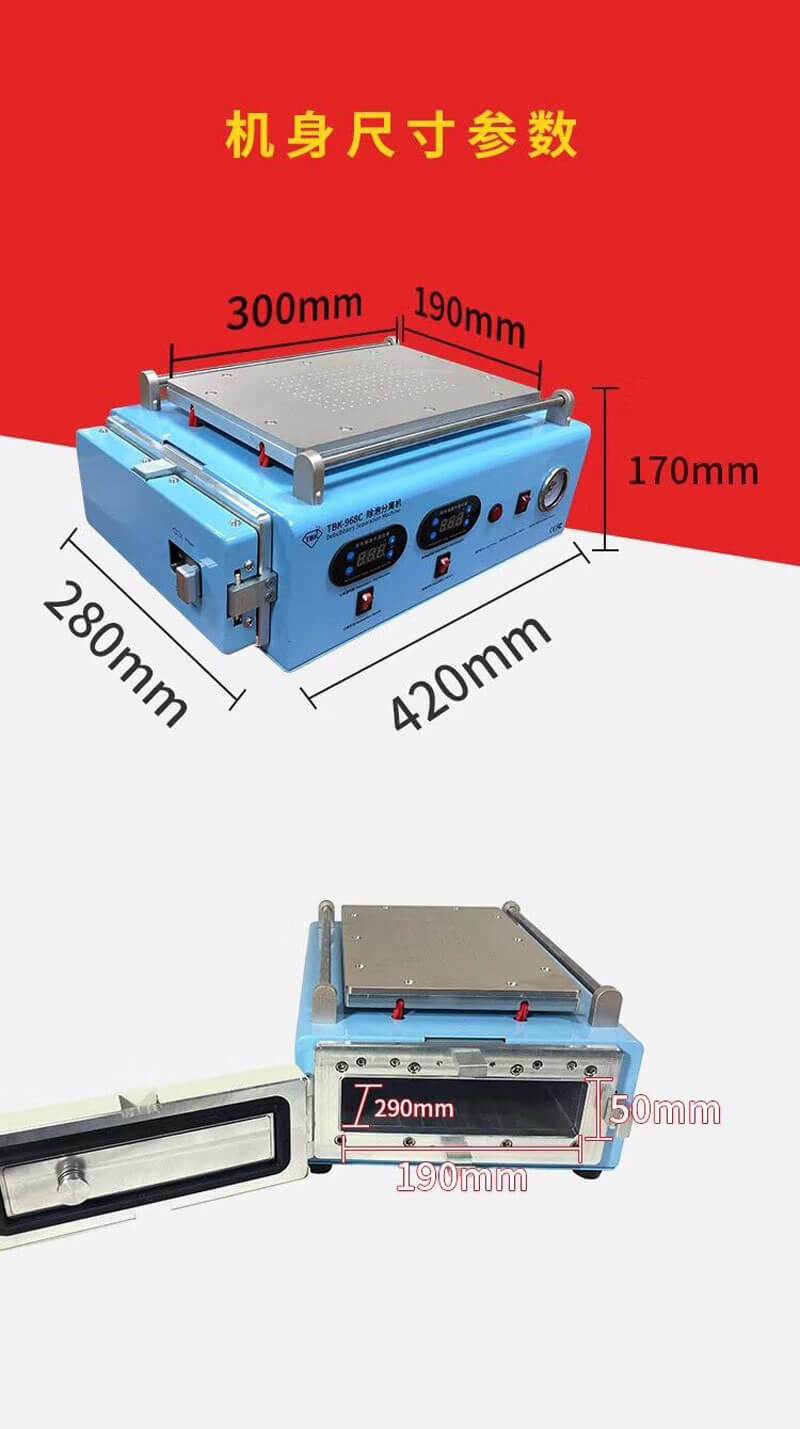

Voltage: 100-240V

Power: 400W

Separate Size: 300*190mm

Net Weight: 13kg

Gross Weight: 18kg

Debubble Size: 290*190*50mm

12 inch vacuum pump built-in separator

Built-in 12 inch OCA autoclave debubble machine

If use debubble function need to link with air compressor.

Built-in 12 inch OCA autoclave debubble machine

If use debubble function need to link with air compressor.

How to use it:

1. Turn on the power: Insert the power cord into the power port on the back of the separator and turn on the power switch.

2. Preset temperature: Press the SET button to preset thetemperature, press the up button to set the temperature toabout 85 degrees, and press NET to save.

3. Prepare wire handle: Equipped with wire handle to separatethe screen.

4. Place the silicone anti-skid pad: Place it on the panel of theseparator Align the pad with the panel holes.

5. Preparation for screen separation: Put the screen to beseparated into the center of the panel, press the start buttonto start vacuum adsorption, and make sure that the screen issucked.

6. Start cutting screen: the screen can be preheated for 3-5minutes to start cutting.

7. After separating the burst screen, turn off the power of theseparator. If it is dry glue, you can tear it off directly by hand

2. Preset temperature: Press the SET button to preset thetemperature, press the up button to set the temperature toabout 85 degrees, and press NET to save.

3. Prepare wire handle: Equipped with wire handle to separatethe screen.

4. Place the silicone anti-skid pad: Place it on the panel of theseparator Align the pad with the panel holes.

5. Preparation for screen separation: Put the screen to beseparated into the center of the panel, press the start buttonto start vacuum adsorption, and make sure that the screen issucked.

6. Start cutting screen: the screen can be preheated for 3-5minutes to start cutting.

7. After separating the burst screen, turn off the power of theseparator. If it is dry glue, you can tear it off directly by hand